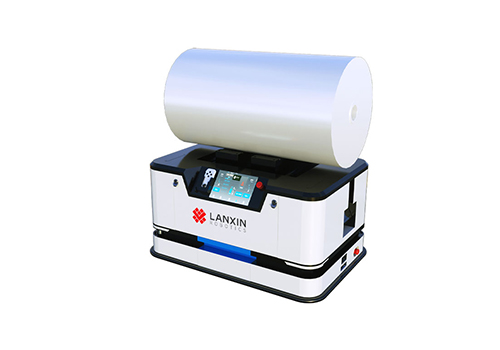

VMR-FR3300L

Case Study

Meet Whole Process Traced in Dish-washing Machine Factory

Spot Mobile Phone Factory Feeding Efficiency Greatly Improved

Automatic Raw Material Distribution and Waste Recycling at Laptop Factory

Case Study

Program to Protect Workers and Materials at Desay

Manpower Liberation at Power Battery Manufacturers

Spot High Precision and High Safety Achived by AMR

Case Study

Cell Transfer with AMR at Permanent Magnet Ferrite Manufacturer

Heavy Weight Transfer Liberated by Robots

Smart Manufacturing Transformation Achieved at HUANSHENG SOLAR

Case Study

Saving More Than 80% of Labor Handling Cost in YUTO

Robots Handle High-risk Goods Instead

Passports Delivered by Roller Robots at Public Security Bureau

Contact Us

Lanxin Technology, 7-802,

China Artificial Intelligence Town,

No.1818-2 Wenyi West Road,

Hangzhou, Zhejiang, China

marketing@lanxincn.com

Popular Products

Cases

Industry